Hydraulic Grab

Description of Patent #: 693222, 8203798, 9904105 etc.

Title:

Hydraulic Grab Machine for an Excavator, Excavators, and its uses,

particularly in the Field of Forestry and Restoration

Technical Field

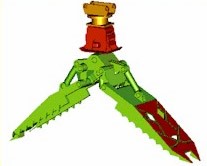

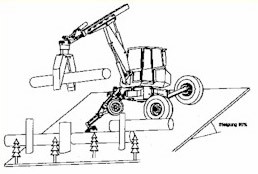

The present invention relates to a grab designed primarily for an excavator or similar device, with two grab arms capable of moving between an opened and a closed position and fixed to a fastening head. Further, the invention relates to uses of the grab, particularly in the field of forestry. Finally, it relates also to another excavator with special equipment or design as regards the grab and the uses stated.

The increasing deforestation of forests, especially rainforests in tropical or subtropical regions, is regarded as a major ongoing problem for both the environment and the world's climate. Efforts to limit deforestation have not proven very successful up to now. Moreover, the success achieved with reforestation of deforested areas has been quite modest also. In fact, so far, reforestation has not even begun to keep pace with deforestation.

Experience shows that on reforestation projects only a small amount of the saplings planted between stumps of the felled trees actually succeeds in growing. A further amount is eaten by animals or is simply smothered by more rapidly growing ground plants.

The current State of Technology

Whilst very effective machines and techniques are available for tree felling and evacuation, up to now there has been no comparably effective device or technique for use in reforestation.

Presentation of the Invention

(documented by virtual pictures)

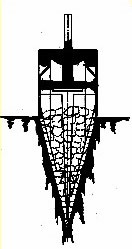

The aim of the present invention is to help remedy this problem. It does so consistently by creating a grab as stated above for an excavator or similar device. The grab arms of the grab are so designed that in their closed position they form an acute-angled split- or drill-wedge.

Fitted onto the arm of an excavator, the invented grab can be used advantageously to plant saplings. During this process, the grab can be used in its closed position, where it forms an acute-angled split-wedge, to create a plant hole by insertion of the wedge into the desired planting site. In its normal use configuration and without any change of tools, the same grab can then be used to grasp a sapling, e.g. a young fir tree, and place it into a plant hole.

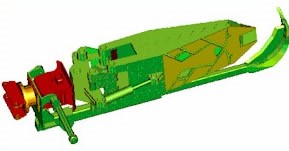

The grab, used in combination with a hydraulic hammer fitted onto the excavator arm, would be the preferred instrument for inserting the wedge-shaped grab effectively into the ground at the planting site.

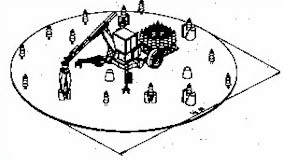

The planting technique described becomes particularly efficient when an excavator is used which is equipped within the swing-area of its arm, and thus of the grab itself, with carrier devices in the form of basket-like containers or plate-like palettes. These are intended for such tasks as the reception, transportation and storage of unplanted saplings.

Since severely deforested wooded areas are most often located in mountainous regions with generally poor accessibility and impassability, a walking excavator is especially appropriate as an excavator.

Of course, instead of an excavator, another machine or vehicle could be used, such as a truck equipped with an excavator-boom. In this case, the unplanted saplings could be carried advantageously on the load surface ready for planting. Conversion work requires the hydraulic equipment only to be fitted.

It is particularly preferable to place the young saplings actually into or near by the old tree stumps of felled trees, rather than in the soil between them.

This technique has the following principal advantages:

- The growing sapling is considerably better protected when located into or near by the old stumps than between stumps, especially if the stumps are, as is the case with rainforest, quite large, i.e. thick and high. This form of protection is also effective against big game, which otherwise would consume or trample growing samplings.

- The old stump offers the growing sapling sufficient nutrients for growth. Most of the planted saplings will survive, grow and develop extremely well.

- On top of or near by the tree stumps, saplings do not compete with other ground plants, and hence can develop with less disruption.

Despite these major advantages, this planting technique has been little used until now. This is due mainly to the fact that making a suitable plant hole in or near by the tree stump, e.g. by hollowing one out in it, has been an extremely arduous task. However now, the invented grab can create a suitable plant, simply by splitting the moldered stump or the soil with roots near the stump by using the wedge-shaped grab and a hydraulic extension arm as a splitting device.

Using the grab proposed by the invention, especially in combination with a hydraulic hammer or vibrator and a sufficiently strong excavator configured as stated above, also allows larger saplings than hitherto to be handled. This is because the machinery alleviates the need for virtually all manual tasks, since it performs them itself. The saplings used may even be 100 - 150 cm tall. The chances of saplings of this size being able to prosper against pests or other harmful influences are far higher than those of saplings of less than 50 cm tall, as are normally used. The time required for forest cover to grow back is of course far less if larger saplings are used, something which constitutes another advantage.

To enable use in combination with a customary hydraulic hammer or vibrator, the fastening head of the invented grab should be specially designed to fit inside or integrate a hammer's chuck.

Preferably, the grab cutters should also include a moveable and/or retractable arm. One of the items this arm can be fitted with is a telescopic cylinder. By virtue of the grab cutters' intrinsic mobility, in addition to serving as anchors during actual planting operations, they can be used to support forward movement across terrain. For example, a walking excavator equipped with such grab cutters could literally drag itself forwards, or use the grab cutters to push off with; or even as additional supports.

Additionally and to some advantage, the grab can be fitted with devices enabling liquid to be introduced between the grab arms. This capability could be used to irrigate or spray saplings during the planting process.

The grab arms of the grab should be designed in such a way that in their closed position, they form a mainly closed containment area inside the tip of the wedge. This feature would enable plant earth to be grasped by the grab and then inserted into the plant hole along with the sapling.

So as to facilitate the wedge's insertion into the ground, the grab arms can be tapered or narrowed right up to their tip. Although this ensures less resistance, it also reduces the containment volume and gripping capacity of the grab.

Where the subsoil is very hard, a specially sharpened tip with four or eight edges can be used. Such a grab would be particularly suitable for constructing large fence installations.

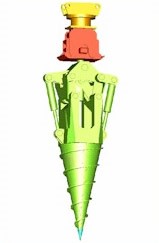

In desert-like regions, where the subsoil is dry, the most suitable version of the grab is one where the grab arms are cone-shaped and mounted, preferably, on an endless hydraulic rotating plate. To this end, both grab arms interlock using closure pegs. For such applications, special grabs equipped with a hard cutting surface such as a diamond tip could be used.

To enable versatile use of the invented grab, grab arms of the same series would be interchangeable, a feature which would keep conversion costs fairly low.

The invented grab has uses beyond forestry. It is also extremely suitable for constructing items such as major fence installations or avalanche or mountain torrent defence works. Generally, this means that holes must be made in the ground, and then a post or similar structure inserted. Also, the hole could be filled with liquid concrete, using the containment area formed by the grab when it closes.

Furthermore, the grab can be used also for ground stabilisation.

First, the grab with its grab arms closed, forms a split-wedge and then inserts this wedge into the ground, thereby creating a reception hole. Second, the grab arms are used to inject fill such as stones, gravel, tree trunk material, sand bags, etc. more or less directly into the hole. This method would enable stabilisation of hillsides endangered by landslides, river embankments, dams or similar structures.

There is a rising world-wide need to perform reforestation and repair activities faster, more economically and with greater mobility.

This imperative is dictated in turn by the need to satisfy and meet increasing safety, quality of life and environmental protection demands.

The world-wide water supply on the continents can only be guaranteed and protected by a healthy forest economy.

Each clear-cut, not being reforested and stabilised, will convert into a desert and is loosing its soil value for plantations.

A dangerous and dramatic future disaster for world's food supply and climate - if today's human society, only because of its addiction to profit - does furthermore ignore and neglect the urgent needs for an intensive world-wide reforestation.

In May 1998, the Patentee, Founder and President of the Company: Robert Schnyder